35 cause and effect diagram six sigma

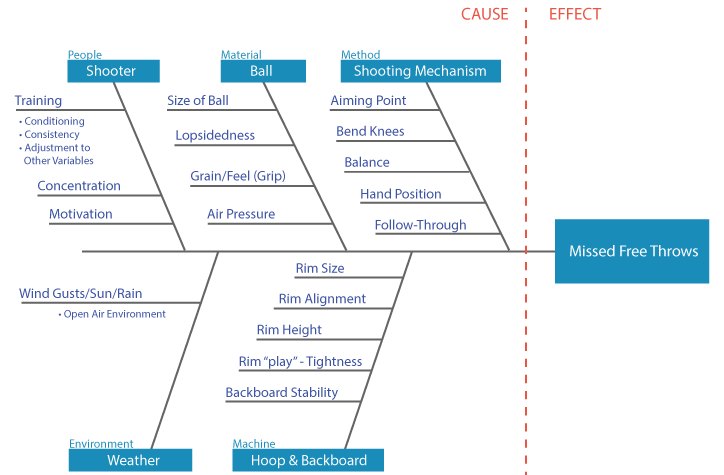

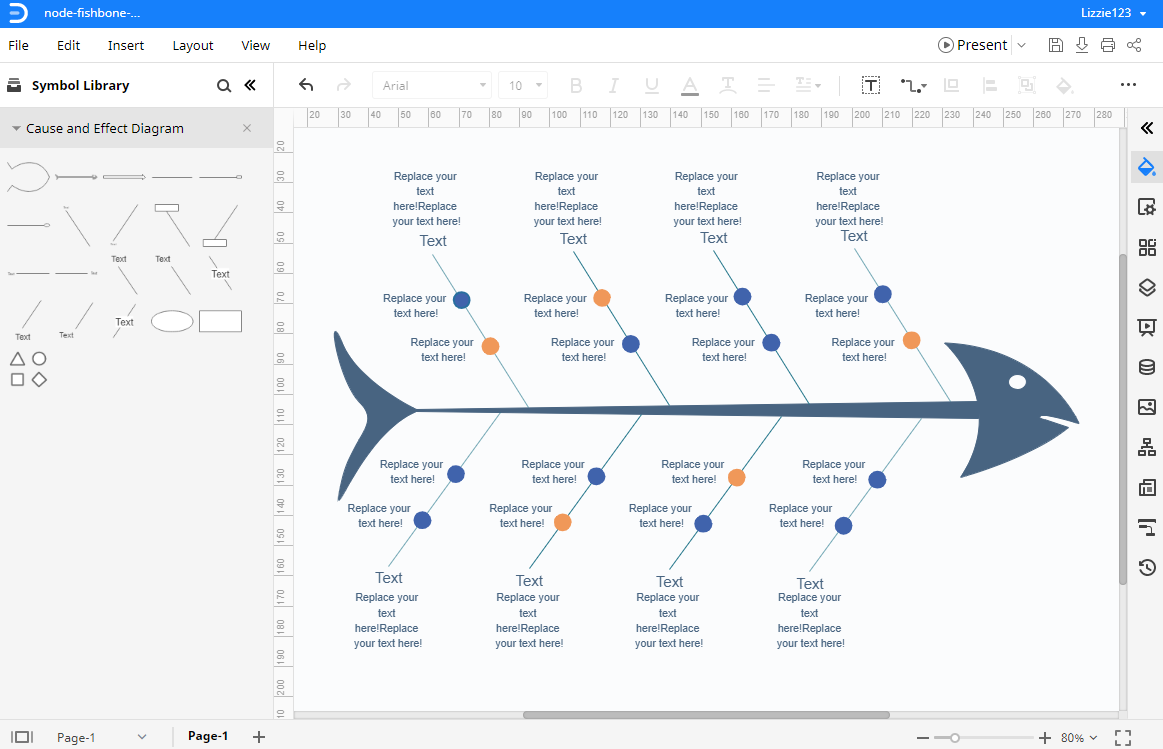

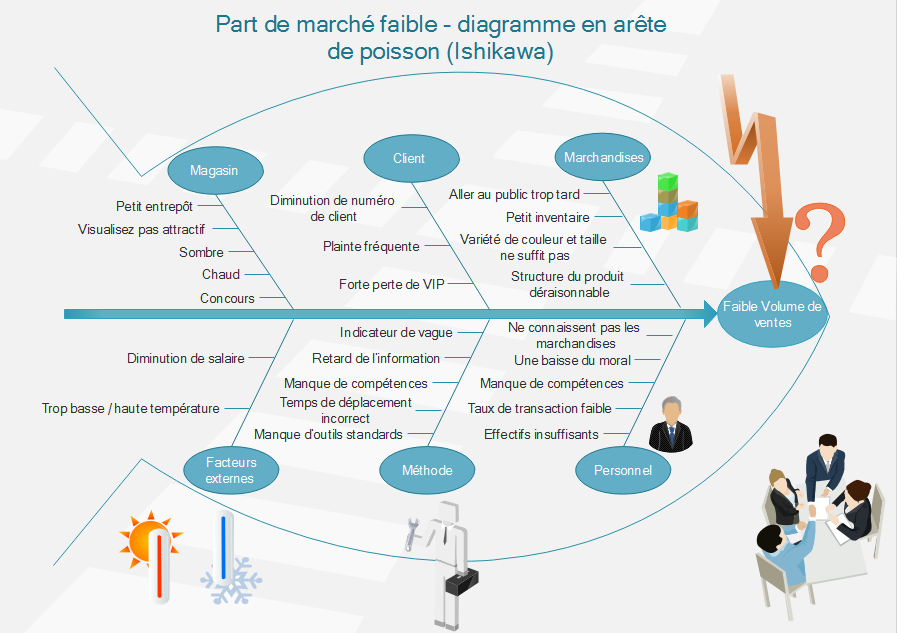

Jun 30, 2021 · Fishbone (aka Cause and effect/Ishikawa) diagrams are great for analyzing processes and identifying defects in them. They are a great way to visualize causes and their effects. Fishbone diagrams are used in many industries but primarily they’re used in manufacturing, sales, and marketing. Below are some fishbone diagram templates from our diagramming community. 5 Whys and the Fishbone Diagram. The 5 Whys can be used individually or as a part of the fishbone (also known as the cause and effect or Ishikawa) diagram. The fishbone diagram helps you explore all potential or real causes that result in a single defect or failure. Once all inputs are established on the fishbone, you can use the 5 Whys ...

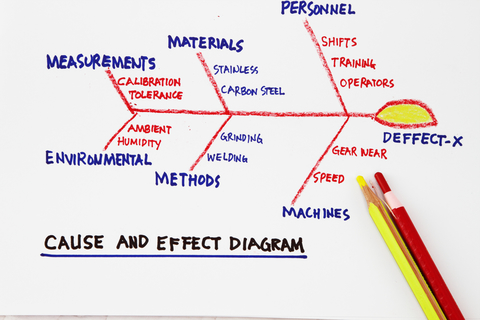

A cause/effect diagram was first known by the name fishbone diagram because it looks like the skeleton of a fish. It was first made popular by Dr. Ishikawa back in the late 1970s and early 80s. Usually the cause/effect diagram is drawn on a large whiteboard or a large flipchart. The effect is usually written at the 3 o’clock position. A horizontal line divides the whiteboard into two equal ...

Cause and effect diagram six sigma

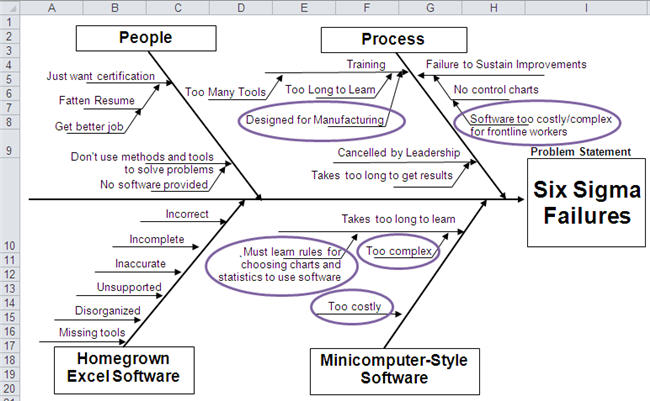

A Cause and Effect Diagram is a graphical tool for displaying a list of causes associated with a specific effect. It is also known as a fishbone diagram or an Ishikawa diagram (created by Dr. Kaoru Ishikawa, an influential quality management innovator). The graph organizes a list of potential causes into categories. The Cause and Effect Diagram shown here happens to have six branches. There is ... The Cause and effect matrix is a Lean Six Sigma tool used to prioritize the key process input variables (KPIVs) based on priorities of customer outputs (KPOVs). In other words, it establish the correlation between process input variables to the customer’s outputs during root cause analysis. The cause and effect (fishbone) diagram will help you visually display the many potential causes for a problem or effect. Don't be fooled by tool rules; Kerri Simon teaches you to modify the tool for your specific project and subject matter. Free templates are included so you can begin using this tool today.

Cause and effect diagram six sigma. (Ishikawa Diagram or Cause & Effect Diagram) Description: The Fishbone Diagram was originally created by Kaoru Ishikawa to find process imperfections (Ishakawa, 1985). The first company to adopt the diagram in all of its processes was Kawasaki Iron Fukiai Works in 1952. 6M/6M's is a mnemonic tool used primarily used when it comes to problem-solving or decision making. The Cause and Effect diagram, also known as Fishbone Diagram, proves extremely beneficial when exploring or dissecting any production or industrial operations problems.It is a problem-solving technique that identifies the likely causes of a challenge and undertakes to fix it. Cause and Effect (Fishbone) Diagram A cause and effect diagram, also known as a "fishbone" diagram, can help in brainstorming to identify possible causes of a problem and in sorting ideas into useful categories, which is a common tool using in six sigma programs for root cause analysis. The fishbone will help to visually display the many potential causes for a specific problem or effect. Also called: cause-and-effect diagram, Ishikawa diagram. Variations: cause enumeration diagram, process fishbone, time-delay fishbone, CEDAC (cause-and-effect diagram with the addition of cards), desired-result fishbone, reverse fishbone diagram This cause analysis tool is considered one of the seven basic quality tools. The fishbone diagram ...

Here's a vivid cause and effect diagram in the shape of a fish. All the elements are in blue with white background, making the fishbone diagram clean and modern. With Edraw's wide range of tools and easy-to-use editor, you'll have your desired design in no time. A cause and effect diagram, also known as an Ishikawa or "fishbone" diagram, is a graphic tool used to explore and display the possible causes of a certain effect. Use the classic fishbone diagram when causes group naturally under the categories of Materials, Methods, Equipment, Environment, and People. The Cause and Effect Diagram (aka Ishikawa, Fishbone) introduced by Kaoru Ishikawa (1968) that show the causes of a specific event. He also introduced the company-wide quality control (CWQC) and also Quality circles concept in Japan. Common uses of the Ishikawa diagram are product design and quality defect prevention, to identify potential factors causing an overall effect. Feb 20, 2021 · A cause and effect matrix relates process steps to inputs and correlates to process outputs. Customer requirements are ranked by order of importance and then inputs and outputs are rated by their interaction impact. It relates the key inputs to the key outputs (customer requirements) using the process map as the primary source. How

May 01, 2018 · The most important consideration in the construction of a cause-effect diagram is a clear understanding of the cause-effect relationship. When one has completed the diagram, one should be able to start at any endpoint and read the diagram as follows (using Figure 29 as an example): “Snow causes the road to be slippery. Definition of Cause and Effect Diagram: A cause and effect diagram is a visual tool used to logically organize possible causes for a specific problem or effect by graphically displaying them in increasing detail. It helps to identify root causes and ensures common understanding of the causes. It is also called an Ishikawa diagram. There are several quality control tools in Six Sigma, one of them being the fishbone diagram.It is mainly used in root cause analysis, particularly in the Analyze phase of the DMAIC methodology. Sometimes you will hear it being called the cause and effect diagram when project managers are using it for quality management. Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams, or Fishikawa) are causal diagrams created by Kaoru Ishikawa that show the potential causes of a specific event.. Common uses of the Ishikawa diagram are product design and quality defect prevention to identify potential factors causing an overall effect. Each cause or reason for imperfection is a ...

A Fishbone Diagram is a structured brainstorming tool designed to assist improvement teams in coming up with potential root causes for an undesirable effect. Its name derives from its resemblance to the bones of a fish. It is also known as a Cause and Effect Diagram or …

The cause and effect (fishbone) diagram will help you visually display the many potential causes for a problem or effect. Don't be fooled by tool rules; Kerri Simon teaches you to modify the tool for your specific project and subject matter. Free templates are included so you can begin using this tool today.

The Cause and effect matrix is a Lean Six Sigma tool used to prioritize the key process input variables (KPIVs) based on priorities of customer outputs (KPOVs). In other words, it establish the correlation between process input variables to the customer’s outputs during root cause analysis.

A Cause and Effect Diagram is a graphical tool for displaying a list of causes associated with a specific effect. It is also known as a fishbone diagram or an Ishikawa diagram (created by Dr. Kaoru Ishikawa, an influential quality management innovator). The graph organizes a list of potential causes into categories. The Cause and Effect Diagram shown here happens to have six branches. There is ...

Fishbone Diagram Ishikawa Cause And Effect Diagram Knowledge Swami Com Fishbone Diagram Ishikawa Cause And Effect Diagram Knowledge Swami Com Fishbone Diagram Ishikawa Cause And Effect Diagram

Fishbone Diagram Ishikawa Cause And Effect Diagram Knowledge Swami Com Fishbone Diagram Ishikawa Cause And Effect Diagram Knowledge Swami Com Fishbone Diagram Ishikawa Cause And Effect Diagram

0 Response to "35 cause and effect diagram six sigma"

Post a Comment