37 plate heat exchanger diagram

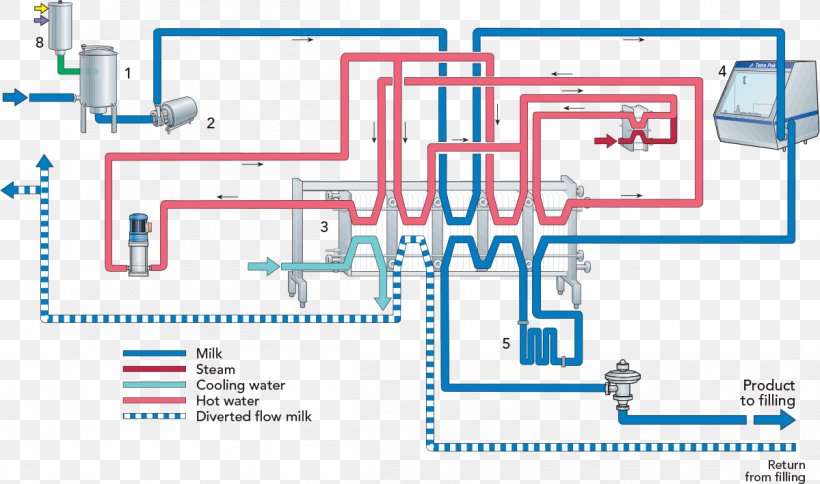

PDF Brazed Plate Heat Exchangers - AIC The design of the double wall brazed plate heat exchanger prevents cross contamination of fluid streams if there is an internal leak within the unit. Two stainless steel plate walls separate the fluid streams, with an air gap in between. In the event of a leak, the affected fluid will flow into the air gap and escape out of the heat exchanger, PDF Plate Heat Exchangers Hoval - Innergy Tech ence between the air streams in the plate heat exchanger is greater than when there is no condensation. Also the heat transfer is better; consequently the efficiency is raised significantly.This can be seen clearly in the hx diagram. The cold air stream is heated more than the warm air is cooled.

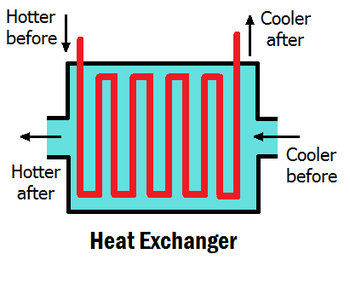

Types of Heat Exchanger: Parts, Working, Advantages, Uses ... A heat exchanger is a system that is very important for transferring heat from one medium to another (liquid, vapor, or gas). Heat exchangers are used in both situations where cooling or heating is required. According to the type of heat exchanger used, the heat transfer process can be carried out as gas to gas, liquid to gas, or liquid to liquid.

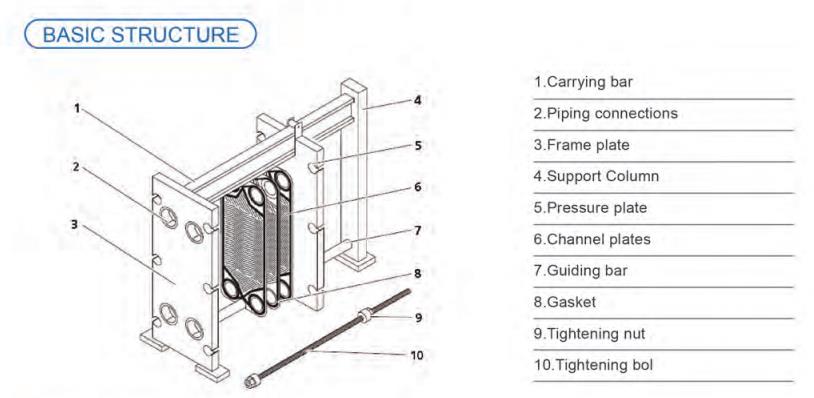

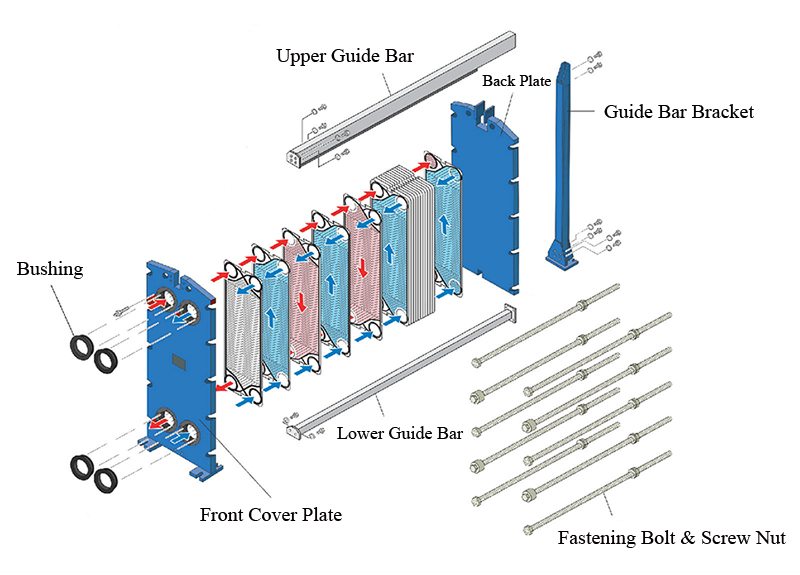

Plate heat exchanger diagram

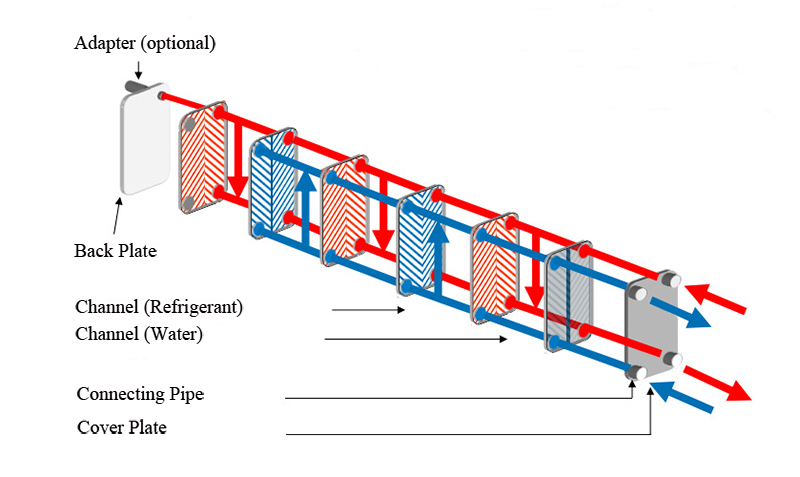

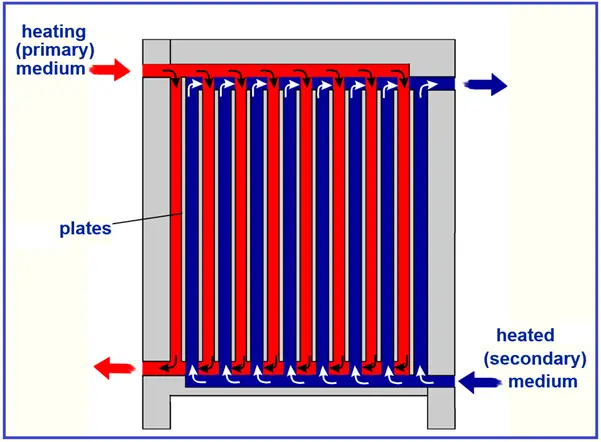

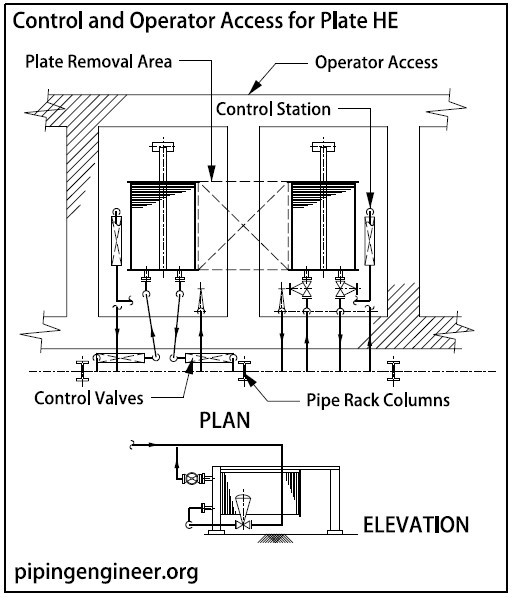

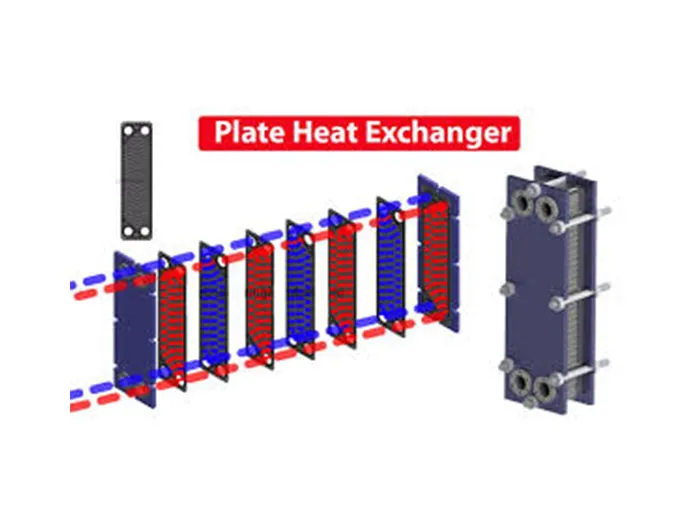

Shell & tube heat exchanger diagram - EnggCyclopedia Following diagram is the structure of a TEMA style shell and tube heat exchanger.The diagram itself is based on the TEMA standards. This diagrams illustrates all the important parts in the construction of a shell & tube heat exchanger, as per the TEMA standards. Plate Heat Exchangers Layout - The Piping Engineering World Plate Heat Exchanger Construction The exchanger plates have spacing between them for liquid flow. A gasket, set into channels on the periphery of each plate, directs and contains the liquid flow distribution. Ports for inlet and outlet of both hot and cold liquids are stamped into the corners of each plate. Heat Exchanger - Types, Diagram, Working, Applications ... Pipe in pipe heat exchangers diagram Plate type heat exchanger Construction and working of Plate type heat exchanger. It consists of a series of closely spaced parallel plates with fins held in between. The plates separate the two fluids which flow through passages alternately formed between the plates.

Plate heat exchanger diagram. PDF Plate and Frame Heat Exchanger Piping Diagram Created Date: 12/20/2012 10:29:06 AM Plate & Frame Heat Exchangers Explained - Thermaxx Jackets Plate and frame heat exchangers are made of corrugated plates on a frame. This design creates high turbulence and high wall shear stress, both of which lead to a high heat transfer coefficient and a high fouling resistance. F luids travel within the heat exchanger. The two streams flow counter currently. Schematic diagram of plate heat exchanger Schematic diagram of plate heat exchanger There are openings in the four corners of the plate, which are assembled together to form a plate bundle to form a fluid to obtain a distribution pipe and a collection pipe. After the heat of the cold / heat medium is exchanged HOME ABOUT US PDF PFX Plate and Frame Heat Exchanger The plate heat exchanger should be installed with approximately 3 feet of open space around it for future maintenance. Under special considerations for space, these dimensions may be reduced but servicing the heat exchanger may be compromised.

PDF Instruction Manual for Brazed Plate Heat Exchangers F1 F2 PLATE HEAT EXCHANGERS F1 F2 F1 F2 F1 F2 F3 F3 F4F3 F1 F2 F3 F4 F4 F4 F5 F5 F6 F6 H H H H L L L L D650 F1 F2 F6 F3 F5 F1 F2 F6 F3 F5 F4 EN. CONNECTIONS All connections are brazed to the BPHE in the general vacuum-brazing cycle, a process that gives a very strong seal between the connection and the cover plate. However, note the following Plate Heat Exchanger (PHE) Explained - saVRee Introduction. Plate heat exchangers are one of the most common types of heat exchanger employed today; the other common type of heat exchanger is the shell and tube heat exchanger.The spiral heat exchanger is also used for industrial applications, but its use is minor compared to the other two types of heat exchanger. How To Install a Plate Heat Exchanger on a Hot Water Tank A plate heat exchanger is used to extract the heat from the wood furnace to distribute it throughout the house. What if there were a way to heat your home, give you all the hot water you need for baths, showers, laundry, heating your pool, spa, and anything else you wanted to keep warm with a truly efficient and renewable resource? Plate and Frame Heat Exchanger - Central Washington University heat transfer rate for this heat exchanger, the hand calculations can also be found in Appendix A. The second method of analysis, which will provide the ideal heat transfer rate, were derived with: Heat Transfer Equation: Q = U*A*n*ΔT lm Hot Water: Cold Water: Diagram of heat exchanger plate: T h_in = 200 °F T c_in = 60 °F T h_out

PDF Heat Exchanger Fundamentals Figure 1 Tube and Shell Heat Exchanger A plate type heat exchanger, as illustrated in Figure 2, consists of plates instead of tubes to separate the hot and cold fluids. The hot and cold fluids alternate between each of the plates. Baffles direct the flow of fluid between plates. PDF Gasketed plate heat exchangers - Alfa Laval The plate heat exchanger shall be operated by persons who have studied the instructions in this manual and have knowledge of the process. This includes knowledge of precautions regarding media type, pressures, temperatures in the plate heat exchanger as well as specific precautions required by the process. Plate heat exchangers - Alfa Laval - heat transfer ... What type of plate heat exchanger is best? Several factors can influence what type of plate heat exchanger offers the best fit for a specific duty. These can include type of media and refrigerant, design pressure, capacity needs, efficiency demands, serviceability requirements, and many more. PDF Plate Heat Exchanger 1 Installation Manual - Hisaka Plate Heat Exchanger (hereinafter "PHE") performs heat exchanging by transferring heat between hot and cold fluids flowing alternately through heat transfer plates, which are thin metal sheets having fine corrugated patterns.

PDF Plate Heat Exchanger Installation and Operation Manual Figure 4 - Plate Heat Exchanger Part Diagram Figure 3 shows the CCT 4.0 Installed on heat exchanger testing for internal defects. Figure 4 shows the typical frame components found on a plate heat exchanger. 8 5.2 Port Identification, Location and Labeling

Plate and Frame Heat Exchangers Plates are pressed in materials between 0.5 and 1.2 mm thick and plates are available with effective heat transfer area from 0.03 to 3.5 m 2. Up to 700 plates can be contained within the frame of the largest Paraflow exchanger, providing over 2400 m 2 of surface area. Flow ports and associated pipework are sized in proportion to the plate area ...

PDF hot water manual 01-24-2022 - Energy Kinetics Plate heat exchanger piped as a hot water zone. 3. Indirect tank with internal heat exchange coil, fed by a circulator or zone valve (see underlined below). 4. Hot water making kits, applied to boilers made by other manufacturers. 5. Commercial applications with primary/secondary loop heating. 6. Trouble shooting and diagnostics for plate heat ...

PDF APV Gasketed Plate Heat Exchangers - Instruval Figure 1: Main components of APV gasketed plate heat exchanger, industrial design 1. Headfor connections and clamping the plate pack 2. Followerfor clamping the plate pack and any additional connections 3. End support for supporting the top and bottom bars 4.

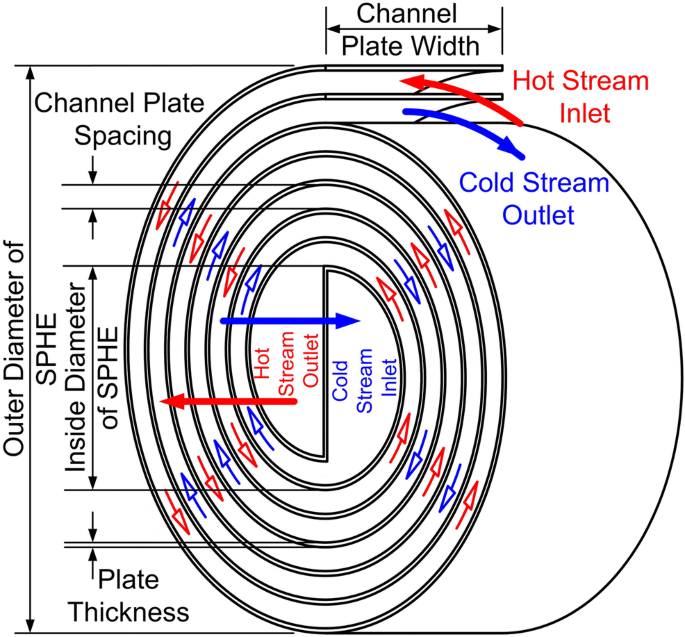

Schematic diagram of the plate heat exchanger [11 ... Fig. (1), schematic diagram of the plate heat exchanger is depicted. It is incorporated of a mound of parallel thin plates which are assembled between heavy end plates. Where heat is exchanged...

Plate heat exchanger - Wikipedia Schematic conceptual diagram of a plate and frame heat exchanger. An individual plate for a heat exchanger The plate heat exchanger (PHE) is a specialized design well suited to transferring heat between medium- and low-pressure fluids.

Plate Heat Exchanger Working Principle, How a Plate Heat ... PLATE HEAT EXCHANGERS . Heat Exchangers. Plate Heat Exchangers were first produced in the 1920s and have since been widely used in a great number of sectors.. A plate exchanger consists of a series of parallel plates that are placed one above the other so as to allow the formation of a series of channels for fluids to flow between them.

P&ID Symbols for Heat Exchangers - The Piping Engineering ... Heat Exchanger 01: Heat Exchanger 02: Heat Exchanger 03: Heater: Induced Draft Cooling Tower: Induced Flow Air Cooler: Kettle Heat Exchanger: Oil Burner: Plate and Frame Exchanger: Plate Exchanger: Plate Heat Exchanger: Reboiler 01: Reboiler 02: Shell and Tube Heat Exchanger 01: Shell and Tube Heat Exchanger 02: Shell and Tube Heat Exchanger 03 ...

PDF Engineering Design Guidelines Plate Heat Exchanger temperature side. But designing heat exchanger might be a challenge; it needs iteration for manual calculation. Hence, a guideline to properly select and sizing is needed. An innovative type of heat exchanger that has found widespread use is the plate and frame (or just plate) heat exchanger, which consists of a series of plates with corrugated

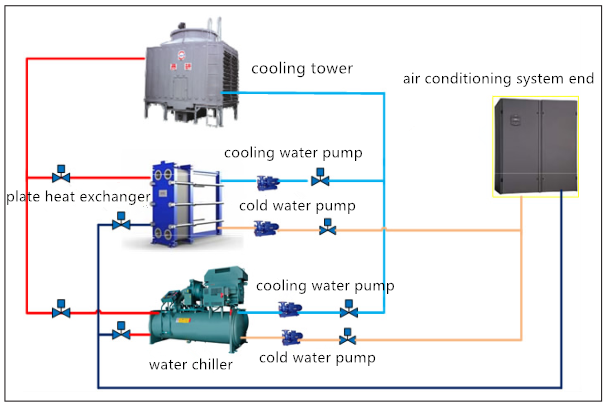

Secondary Chilled Water Loop - Plate Heat Exchanger: Plant ... Secondary Chilled Water Loop - Plate Heat Exchanger. The Secondary Cooling system is constructed by using a PlantLoop object, the working fluid in this loop is water. It uses one side of a plate heat exchanger (modeled using a HeatExchanger:FluidToFluid object) to supply chilled water to a cooling coil (modeled by using a Coil:Cooling:DetailedGeometry object).

Schematic diagram of plate heat exchanger circulation Schematic diagram of plate heat exchanger circulation 2020-11-18 Plate Heat Exchanger is a kind of high efficiency heat exchanger which is composed of a series of corrugated metal sheets.A thin rectangular passage is formed between the plates through which heat is exchanged.

Heat Exchanger - Types, Diagram, Working, Applications ... Pipe in pipe heat exchangers diagram Plate type heat exchanger Construction and working of Plate type heat exchanger. It consists of a series of closely spaced parallel plates with fins held in between. The plates separate the two fluids which flow through passages alternately formed between the plates.

Plate Heat Exchangers Layout - The Piping Engineering World Plate Heat Exchanger Construction The exchanger plates have spacing between them for liquid flow. A gasket, set into channels on the periphery of each plate, directs and contains the liquid flow distribution. Ports for inlet and outlet of both hot and cold liquids are stamped into the corners of each plate.

Shell & tube heat exchanger diagram - EnggCyclopedia Following diagram is the structure of a TEMA style shell and tube heat exchanger.The diagram itself is based on the TEMA standards. This diagrams illustrates all the important parts in the construction of a shell & tube heat exchanger, as per the TEMA standards.

![Schematic of a plate heat exchanger [47]. | Download ...](https://www.researchgate.net/profile/Navid-Khordehgah/publication/324811679/figure/fig8/AS:630480231751687@1527329609086/Schematic-of-a-plate-heat-exchanger-47.png)

0 Response to "37 plate heat exchanger diagram"

Post a Comment